Technology that very few companies can replicate in the world is located in the heart of Illinois.

Recently, Cast Technologies, a foundry and machine shop, transformed their business by adding Makino Automation. The incorporation of mixed-part automation now allows them to run multiple jobs concurrently, increasing efficiency and productivity.

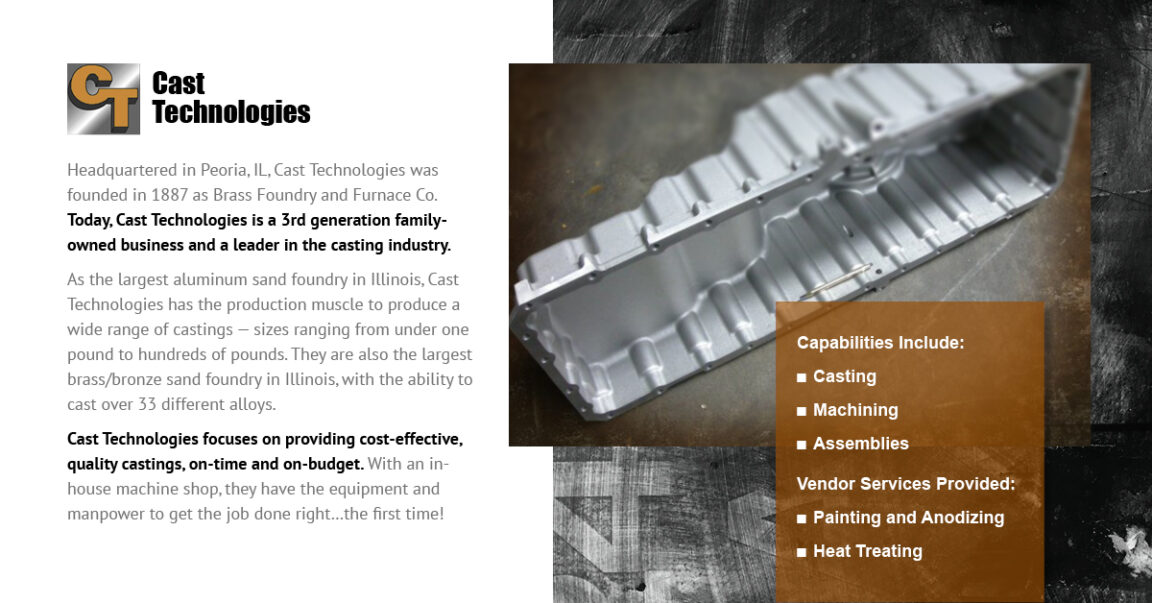

Not only is Cast Technologies among the few companies in the world that have those capabilities, they are also the largest aluminum sand, brass and bronze foundry in Illinois.

The company was founded in 1887 by E.B. Hazen as Brass Foundry and Furnace Co., making Cast Technologies over 130 years old. The third-generation business has grown to be a supplier to several fortune 500 companies, and they currently have 250,000 square feet of shop and office space in Greater Peoria.

The company can produce a wide range of castings of over 33 different alloys, with sizes ranging from ounces to hundreds of pounds. Their products and services include aluminum sand castings, brass and bronze sand castings and in-house machining. Furthermore, they can provide value-added services such as heat treatment, painting and specialty coatings.

With the addition of the Makino Automation machining, Cast Technologies continues to stay competitive. The equipment innovation not only made their processes faster, but it also created several economic advantages for them by minimizing expenses and increasing profits.

Looking to the future, management at Cast Technologies believes they are positioned for any job that comes through their door. They are also looking to expand their capabilities by eventually purchasing additional pallets and machines.

Cast Technologies is a proud member of the Greater Peoria Manufacturing Network, which provides a one-stop manufacturing shop of suppliers and service providers in the area.

To learn more about Cast Technologies, visit their website and stay up to date with the Greater Peoria Manufacturing Network’s latest news and updates.